Description

Product Description

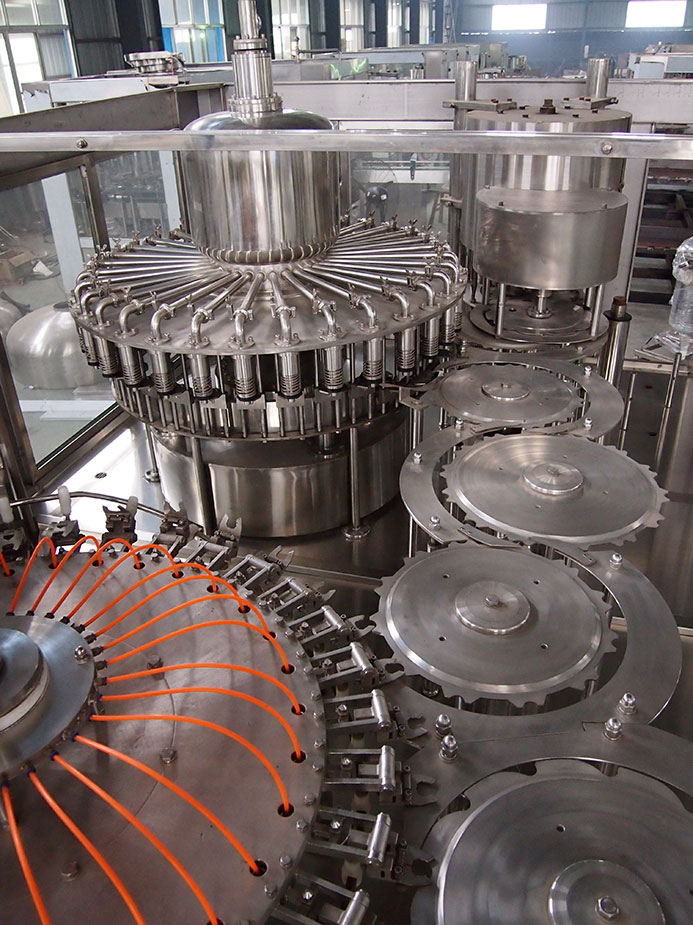

RCGF series 3-1 juice filling machine is mainly used in the beverage filling process. The machine combines washing, filling and capping with complete automation, suitable for filling juice and tea beverage.

Features

- Full juice filling avoids bottle distorted after cooling and reduces dissolved oxygen at the max.degree.

- Product storage hopper and feed system adopts reasonable product feed design(constant flow, constant pressure, no foaming).

- Product hopper with reasonable structure(exhaust, fully close, temperature can be detected).

- Medium and high speed line adopts product distributor instead of larged liquid carousel, which can be cleaned completely by pressure cleaning with CIP.

- Sanitary filling valve system umbrella-flow type structure.

- Product recycle tank system with automatic product feed startup.

Technical Parameter

| Model | RCGF 18-18-6 |

| Washing workstation | 18 |

| Filling workstation | 18 |

| Capping workstation | 6 |

| Production capacity(500ml)(B/H) | 5000 |

| Bottle specification(mm) | Φ=50-95, H=150-310 |

| Motor power(KW) | 4 |

| Overall dimension(mm) | 2550×1850×2200 |

| Weight(kg) | 3000 |

Other models

| Model | Washig heads | Filling heads | Capping heads | Production B/H |

| RCGF14125 | 14 | 12 | 5 | 2500 |

| RCGF16166 | 16 | 16 | 6 | 3500 |

| RCGF24248 | 24 | 24 | 8 | 8000 |

| RCGF323210 | 32 | 32 | 10 | 10000 |

| RCGF404012 | 40 | 40 | 12 | 14000 |

Detailed Photos of Juice filling machine

Working video

About us

We have more than 20 years knowledge and experience on PET Water/juice/carbonated drinks production line. Our exporting product includes: Injection molding machine, PET preform mould, plastic bottle blowing machine, Water treatment system, Juice filling machine and Packaging machine etc.

Q: What is the warranty if we buy your machines?

A: We offer the high quality machines with 1 year guarantee start from the machine reach to your factory. Also your share the lifelong technical support.

Q: How about the spare parts?

A: We will send one year enough spare parts together with machines for your stock. During the warranty time, if some spare parts broke without human problem, we will send free for you.

Q: How to install my machines when it arrives? What is the cost?

A: We will send our engineer to your factory to install the machines and train your engineers how to operate and maintain the machines. Customer pay for visa, round-trip tickets, room and accommodation, also USD80/day/ person(engineer salary).

Q: How long time for installation?

A: According to the machine you order, usually we will send one or two engineer, it takes about 7to 20days.

Q: When can I get my machine after I paid?

A: Usually the production time is around 25-60 days. The exactly will be decided by which machine u order.

zoritoler imol –

I have been surfing online greater than three hours as of late, yet I by no means discovered any fascinating article like yours. It is pretty value sufficient for me. In my opinion, if all webmasters and bloggers made excellent content as you did, the net will be a lot more helpful than ever before.