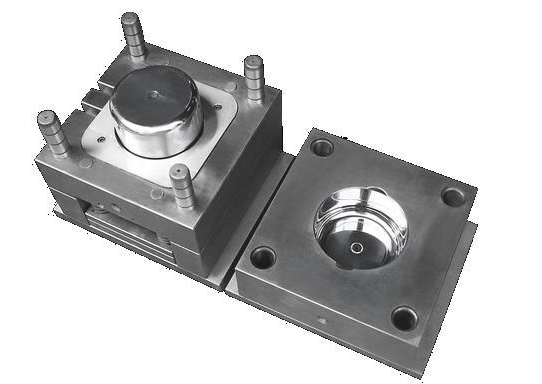

Definition of Injection Mold

The mold used in plastic injection molding is called injection mold. The injection mold can make complex shape, high dimensional accuracy or with inserts plastic product at one time. The injection mold quality has a great influence on the plastic product quality.

Structure and Composition of Injection Mold

- Main Formed Parts

Injection Mold consists of core, cavity, screw, inserts and so on.

2. Gating System

It is a channel that leads molten plastic from the nozzle of the injection machine to the closed mold cavity, usually consisting of main runner, branch runner, sprue gate and a cold slag.

3. Guiding Fitting

To ensure the movable plate and the fixed plate can be accurately aligned when the movable plate is closed, the guide fitting plays the role of guiding and positioning. It is composed of guide pillar and guide sleeve, and some molds are also equipped with guide fittings on the ejector plate to ensure the smooth and reliable operation of the demolding mechanism.

4. Demoulding Structure

There are many structural forms to demould. The most commonly forms are ejector rod, push pipe, ejector plate, rotary ejection and pneumatic ejection. Generally, it consists of ejector rod, reset rod, the ejector rod fixing plate, the ejector plate (ejector ring) and the ejector plate guide pillar / guide sleeve, etc.

5. Core-pulling Mechanism

For plastic parts with side holes and side concave, before being ejected and demoulded, the sliders must be separated by side core pulling (lateral parting) before they can be demolded smoothly.

6. Mold Temperature Control System

To meet the mold temperature requirements, a mold temperature adjustment system is required. Such as cooling water, hot water, hot oil, steam, cold air and electric heating systems to adjust the mold temperature.

7. Exhasut Air System

To discharge the gas from mold, the exhaust groove is oftenly set at the mold parting surface. The gap between the push rods and other movable parts also play the role of exhaust gas.

8. Other Parts

To complete the mold structure, it also need fixed plate, movable/fixed die plate, support pillar, support plate and connecting screw etc.

Thanks for every other informative website. Where else may I am getting that kind of information written in such an ideal approach? I’ve a challenge that I’m just now running on, and I’ve been on the look out for such info.