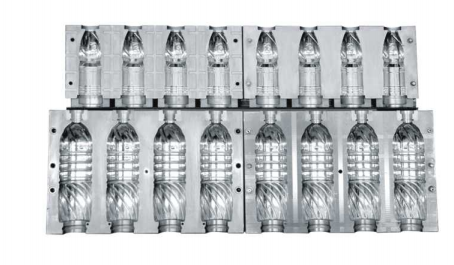

To Keep the PET Bottle Mould in best performance state and extend service life, the worker need pay attention on its maintenace.

Regular inspection and maintenance

1. Daily routine inspection and maintenance:

1.1 Whether the running mold is in normal state

a. Whether there is low voltage mode locking protection;

b. Are moving parts such as guide posts, ejector rods, and travel positions worn, and are they lubricated well? 12 hours per time to refuel. Special structure should increse the time.

c. Whether the screws of the fixed template of the mold and the mold clamp are loose;

1.2 Normal production condition: check whether the defect of the product is related to the mold;

1.3 When getting off the machine, conduct a comprehensive inspection of the mold and carry out anti-rust treatment: wipe off the water in the cavity, core, ejector mechanism and row position, and spray mold anti-rust agent or apply butter.

1.4 The PET bottle mould after getting off the machine should be placed in the designated place and recorded:

(1) PET Bottle Mould condition: intact or need repair

(2) Anti-rust treatment method when lowering the mold.

2. Quarterly routine inspections on PET Bottle Mould:

Does not work exceeding 2 months

2.1 Open the mold and check the internal anti-rust effect. If there is an abnormal situation, the anti-rust treatment must be carried out again. Smeare the PET bottle mould with butter if you do not use it in long time.

2.2 Put it back in place and make a record. Four.

Maintenance Notes:

1. Non-professional maintenance personnel or without the permission of professional maintenance personnel, cannot dismantle the mold for maintenance.

2 If there is a small failure in the production process, the dispatcher can solve it according to the situation. For example: 2.1 Nozzle stick mold: Use a copper needle to knock out at the feed nozzle. Do not use a hard object such as a steel needle to knock the mold. 2.2 There are slight mold marks in the cavity, and the polishing material can be selected according to the smoothness of the cavity. Can not use polishing materials on textured surface. Generally, a copper brush dipped in diamond paste or diamond paste is used for brushing, which is completed by professional maintenance personnel. 2.3 Product sticking to the mold: Generally, the product and the ejection part are covered with hot plastic, and then ejected after cooling. Be careful not to damage the surface of the mold if you burn it with fire.

3. Do not change the PET bottle mould structure at will. If the structure needs to be changed, it can only be carried out after the approval of the quality engineering department.

4. Guarantee the quality of maintenance, select appropriate equipment, materials, tools and methods to solve problems, and complete them as quickly as possible. five.

Make quality inspection records