PET plastic bottle can be divided into two categories, one is a pressure bottle, such as a bottle filled with carbonated beverages; the other is a non-pressure bottle, such as a bottle filled with water, tea, oil, etc. Tea beverages are modified PET bottles mixed with polyethylene naphthalate (PEN) or composite bottles of PET and thermoplastic polyarylate. They are classified as thermobottles and can bear temperature above 80℃. Water bottles are cold bottles and do not have requirement for heat resistance. The hot bottle is similar to the cold bottle in the molding process. This time we mainly discuss the molding process of pressurized beverage bottles in cold bottles

- Equipment

With the continuous advancement of technology and the scale of production, the automation of PET blow molding machines and production efficiency are getting higher and higher. The principle of the equipment is similar. It generally includes five parts: providing preform system, heating system, bottle blowing system, control system and auxiliary machines.

2. Blowing Technology

The main factors affecting the blow molding process of PET bottles include preform, heating, pre-blowing, mold and environment etc.

2.1 Preform

When preparing blow-molded bottles, firstly inject PET chips into preform. The recycled materials should not exceed 5%. The number of recycling should not exceed two times, and the molecular weight and viscosity should not be too low (molecular weight 31000-50000, intrinsic viscosity 0.78-0.85cm³/g). Injection-molded preforms need to be stored for more than 48 hours before using. Preforms cannot be stored for more than six months.

Preform quality largely depends on the PET material quality. Select easyly inflated and shaped material, and a reasonable preform forming process. Experiments show that imported raw materials are easier to blow molding than domestic materials; while the same batch of preforms, different production dates, may has different blow molding processes. The quality of the preform determines the difficulty of the blow molding process. The requirements for the preform are purity, transparency, no impurities, no discoloration, and the length of the injection point and the surrounding halo are suitable.

2.2 Heating

The preform heating is completed by a heating oven. The temperature is manually set and automatically adjusted. In the oven, the far-infrared lamp tube emits far-infrared rays to radiately heat the preform, and the fan at the bottom of the oven conducts thermal circulation, so that the preform wall is heated evenly.

The oven temperature is controlled by the number of turned on lamps, the overall temperature setting, the power of the oven and the heating ratio of each section. Different bottle, the temperature set is different. In order to make the oven function better, the adjustment of its height and cooling plate is very important. If it is not adjusted properly, the bottle neck will become larger and the neck material cannot be pulled evenly.

2.3 Pre-blowing

Pre-blowing is a very important step in the two-step blow molding machine. It means that the pre-blowing starts when the stretch rod is lowered during the blow molding process to make the preform into shape. In this process, the pre-blowing position, pre-blowing pressure and air flow rate are three important process factors.

The shape of normal pre-blown bottle is spindle. The abnormal one is dumbbell, handle shape, etc.The reasons for abnormal is improper heating, lack of pre-blowing pressure and air, etc.. Pre-blowing bottle should keep the same size and same shape during the production process. If there are differences, adjust heating and pre-blowing process.

The size of the pre-blowing pressure varies with the bottle size and equipment capacity. Generally, the capacity is larger, the pre-blowing pressure is smaller; the equipment production capacity is higher, and the pre-blowing pressure is also higher.

Even if the same equipment to produce same bottles , the pre-blowing pressure may different due to the difference in the properties of the PET material. Glass fiber reinforced PET material, small pre-blowing pressure can make the macromolecules at the bottom of the bottle oriented correctly. For other preforms with improper materials or improper molding process, there are a lot of stress concentrations near the injection point that are not easy to subside. If blow molding, it will often blow at the injection point or burst and leak from the injection point during stress testing. At this time, moved 2-3 lamps to the top of injection point to provide enough heat to promote its rapid orientation.

For secondary preforms or storage time exceeds preform, due to the effect of time and temperature differences, they require less heat and pressure.

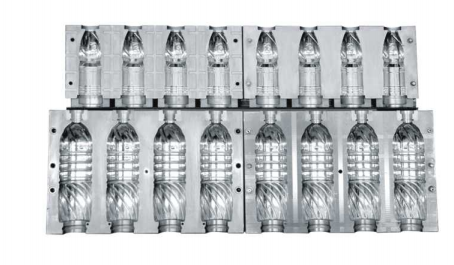

2.4 Mold and Auxiliary Machines

Auxiliary machines include compressor, tank, dryer, filter and chiller. usually control the temperature in 5-8℃.

Mold quality effects the technology adjusting. Such as ribs, the curvature of the transition area and the heat dissipation at the bottom, etc.

2.5 Environment

A constant environment can maintain stable process and product. PET bottle blow molding machine usually installed in room temperature and low humidity site.

Winiber, Provide whole line production of PET bottles. Includes injection machine, PET preform mould, PET blowing machine and its all auxliary machines. If u have interests, pls contact with us!