Description

Product Description

SJ series is and energy saving type PET bottle machine. SJ-3 and SJ-4M is single servo design ( moving preform servo). SJ-3S and SJ-4MS is double servo motor design(moving preform part and clamping part). PET bottle machine can blow any kind of carbonated beverage bottle, sparkling beverage bottle, pure water bottle, mineral water bottle, fruit juice beverage bottle, cosmetic bottes, etc.

PET Bottle Machine Feature

♦Adopt HMI system, easy to operate

♦Machine can connect with filling line directly to prevent the pollution and save labor

♦Unique machine structure design makes the loading preform easily

Technical Parameter

| ITEM | UNIT | SJ-3 | SJ-3S | SJ-4M | SJ-4MS |

| Theoretical Output | Pcs/hr | 3500 | 4000 | 4500 | 5000 |

| Max. Neck Size | mm | 38 | 38 | 38 | 38 |

| Max Capacity | L | 2.0 | 2.0 | 0.6 | 0.6 |

| Max Bottle Height | mm | 320 | 320 | 300 | 300 |

| Max Bottle Diameter | mm | 105 | 105 | 70 | 70 |

| Number of Cavities | ⁄ | 3 | 3 | 4 | 4 |

| Power | 220-380V 50-60HZ | ||||

| Heating Power | KW | 80 | 80 | 80 | 80 |

| Total Power | KW | 85 | 85 | 85 | 85 |

| Main Body Dimension(L×W×H) | M | 3.3×1.9×2.3 | 3.3×1.9×2.3 | 3.3×1.9×2.3 | 3.3×1.9×2.3 |

| Main Body Weight | KG | 2600 | 2600 | 2600 | 2600 |

| Preform Autoloader(L×W×H) | M | 2.0×1.1×2.6 | 2.0×1.1×2.6 | 2.0×1.1×2.6 | 2.0×1.1×2.6 |

| Preform Autoloader Weight | KG | 200 | 200 | 200 | 200 |

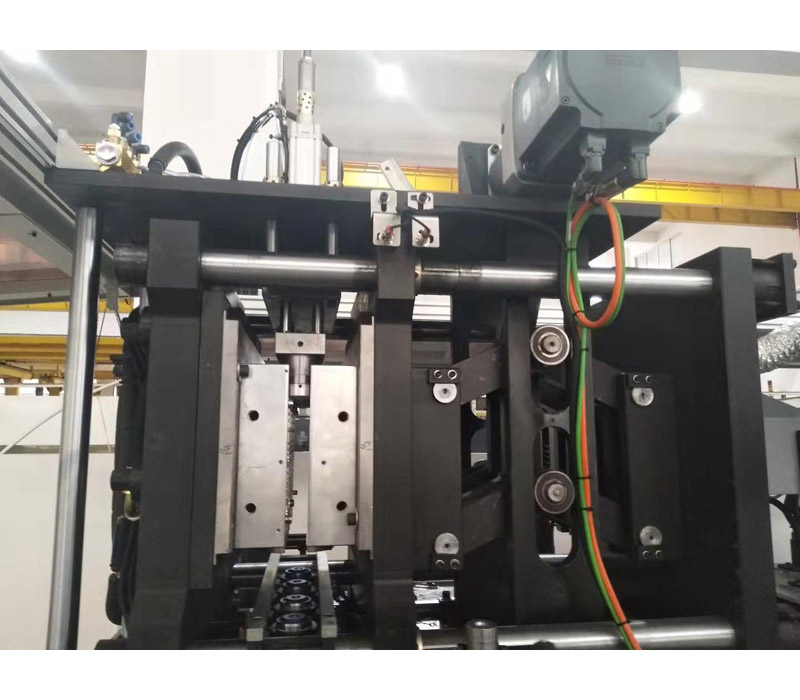

PET Bottle Machine Photo

Working Video

About us

We have more than 20 years knowledge and experience on PET Water/juice/carbonated drinks production line. Our exporting product includes: Injection molding machine, PET preform mould, PET blow moulding machine, Water treatment system, Filling machine and Packaging machine etc.

Q: What is the warranty if we buy your machines?

A: We offer the high quality machines with 1 year guarantee start from the machine reach to your factory. Also your share the lifelong technical support.

Q: How about the spare parts?

A: We will send one year enough spare parts together with machines for your stock. During the warranty time, if some spare parts broke without human problem, we will send free for you.

Q: How to install my machines when it arrives? What is the cost?

A: We will send our engineer to your factory to install the machines and train your engineers how to operate and maintain the machines. Customer pay for visa, round-trip tickets, room and accommodation, also USD80/day/ person(engineer salary).

Q: How long time for installation?

A: According to the machine you order, usually we will send one or two engineer, it takes about 7to 20days.

Q: When can I get my machine after I paid?

A: Usually the production time is around 25-60 days. The exactly will be decided by which machine u order.

graliontorile –

It’s really a great and helpful piece of information. I’m glad that you shared this useful info with us. Please keep us up to date like this. Thank you for sharing.

vorbelutrioperbir –

Hi, Neat post. There’s a problem with your site in internet explorer, would test this… IE still is the market leader and a huge portion of people will miss your excellent writing because of this problem.

smorter giremal –

I love examining and I think this website got some truly useful stuff on it! .

drover sointeru –

You are a very clever individual!

zoritoler imol –

I am also writing to let you understand what a magnificent experience my princess found browsing yuor web blog. She noticed plenty of details, with the inclusion of what it is like to possess an incredible helping mood to let other folks with ease understand specified complex matters. You undoubtedly exceeded visitors’ desires. Many thanks for showing such effective, healthy, informative and in addition cool thoughts on the topic to Julie.