Description

Product Description

15000BPH 32-32-10 Beverage filling machine integrating with washing, filling and sealing, it realizes full automation in the while process, suitable for polyester bottle and plastic bottle filling of mineral water and purified water.

Features of Beverage Filling Machine

- Adopt food grade SUS304 stainless steel material, compact structure, reasonable design, small footprint, production capacity from 2000-36000BPH all can be customized.

- PLC control, touch screen human-computer interaction interface. Easy to operate and maintain. The whole line output can be adjusted and has good compatibility and expansibility.

- Perfect to meet customer needs, has small investment, quick results! It is small and medium size bottled water manufacturers ideal production and processing equipment.

Beverage Filling Machine Technical Characteristics

Beverage filling machine adopts technology of air conveyor direct connect with bottle in feed star wheel to instead of screw and conveyor. It is easier and more simple to change over bottle size. Adopt neck handling technology to convey bottles. There is no need to adjust the height of equipment and only need to change some spare parts.

By 3 in 1 monoblock, the bottle goes through washing, filling and capping with little abrasion, and the transferring is stable, bottle changing is easier. Specially designed stainless steel bottle gripper does not touch the thread parts of bottle neck, avoiding the second contamination. High speed and mass flow filling valve ensures the high filling speed and exact fluid level. Parts touching liquid are all made of excellent stainless steel or food grade engineering plastic. The electric system is from the international brand and achieves the national food hygienic standard. The bottle-out star wheel is helical structure. While changing over bottle size. It is no need to adjust bottle-out conveyor height.

Technical Parameter

| Model | CGF 323210 |

| Washing workstation | 32 |

| Filling workstation | 32 |

| Capping workstation | 10 |

| Production capacity(500ml)(B/H) | 12000-15000 |

| Suitbale bottle specification(mm) | Φ=50-96, H=160-310, Volume=250-2000ml |

| Motor power(KW) | 5.5 |

| Overall dimension(mm) | 3800×2800×2900 |

| Weight(kg) | 4200 |

Other Models

| Model | Washig heads | Filling heads | Capping heads | Production B/H |

| CGF883 | 8 | 8 | 3 | 2000-3000 |

| CGF14125 | 14 | 12 | 5 | 3000-4000 |

| CGF18186 | 18 | 18 | 6 | 5000-7000 |

| CGF24248 | 24 | 24 | 8 | 8000-12000 |

| CGF404012 | 40 | 40 | 12 | 16000-20000 |

| CGF505012 | 50 | 50 | 12 | 20000-24000 |

| CGF606015 | 60 | 60 | 15 | 25000-30000 |

| CGF808020 | 80 | 80 | 20 | 35000-40000 |

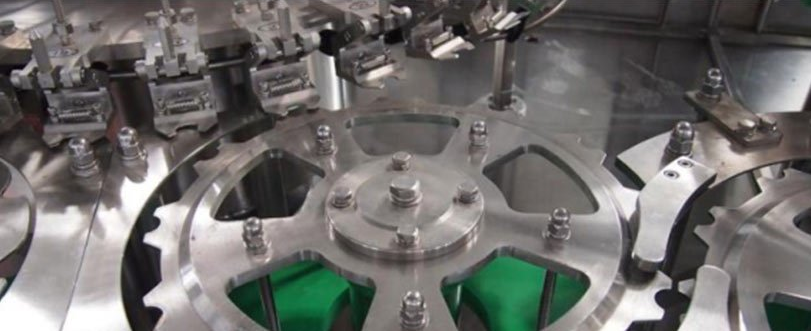

Detailed Photos of Beverage Filling Machine

The overall structure integration

The 3 in 1 unit completed the three processes of washing bottle, filling and sealing.

Stainless steel tube, bottle washing clamp isometric design

Bottle-out star wheel(the transferring is stable)

Adopt neck handing technology to convey bottles. There is no need to adjust the height of equipment and only need to change some spare parts.

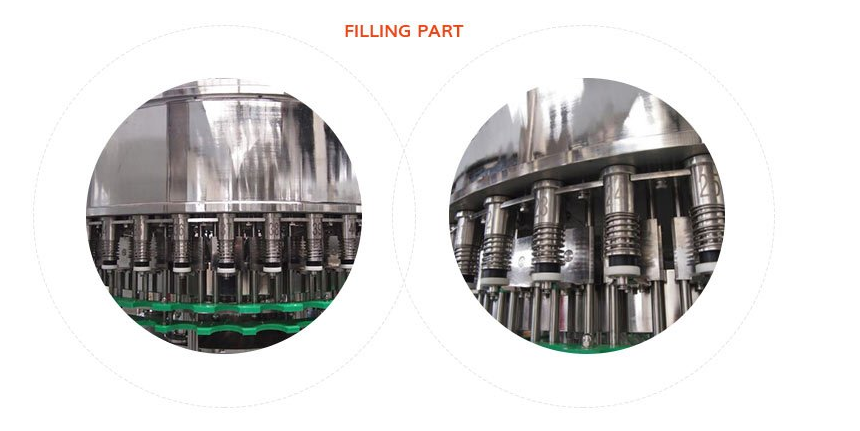

Filling valve(high filling and exact fluid level)

High speed and mass flow filling valve ensures the high filling speed and exact fluid level. Parts contacting liquid are all made of excellent stainless steel or food grade engineering plastic.

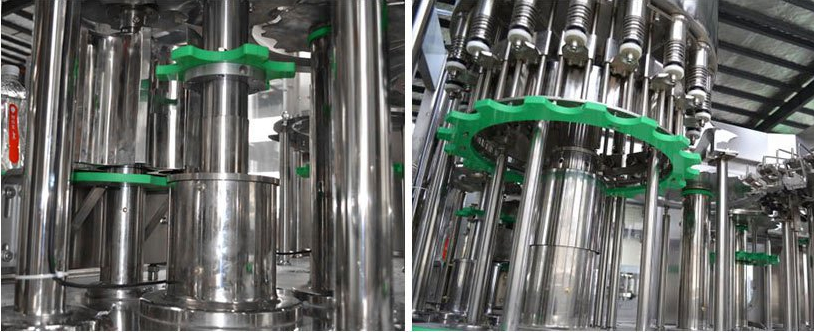

Gland device(bottle change is easier)

Capping head have itself scale. Easier adjust and count.

Screw cap machine spindle plating processing, bearing have itself oil injection hole. Surface protection, concentricity more accurately.

Working video

About us

We have more than 20 years knowledge and experience on PET Water/juice/carbonated drinks production line. Our exporting product includes: Injection molding machine, PET preform mould, plastic bottle blowing machine, Water treatment system, beverage filling machine and Packaging machine etc.

Q: What is the warranty if we buy your machines?

A: We offer the high quality machines with 1 year guarantee start from the machine reach to your factory. Also your share the lifelong technical support.

Q: How about the spare parts?

A: We will send one year enough spare parts together with machines for your stock. During the warranty time, if some spare parts broke without human problem, we will send free for you.

Q: How to install my machines when it arrives? What is the cost?

A: We will send our engineer to your factory to install the machines and train your engineers how to operate and maintain the machines. Customer pay for visa, round-trip tickets, room and accommodation, also USD80/day/ person(engineer salary).

Q: How long time for installation?

A: According to the machine you order, usually we will send one or two engineer, it takes about 7to 20days.

Q: When can I get my machine after I paid?

A: Usually the production time is around 25-60 days. The exactly will be decided by which machine u order.

Reviews

There are no reviews yet.