Description

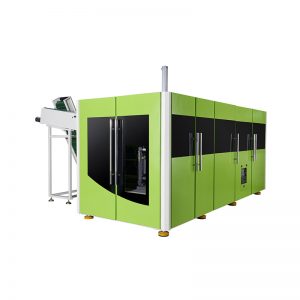

Product Description

Shrink packing machine for packaging production of beer, beverage, pure water, fruit juice, dairy product, etc. With full automatic functions Bottle entering→ Auto unscrambling bottle→ Pushing bottle→ Heat sealing-Cool cutting →Pressing PE→ Shrink→ Cooling.

Features

1. This shrink packing machine applies air-stirring mechanism in pushing bottle and hot sealing-cool cutting.

2.Automatic unscrambling bottle’s appliance makes bottle changing more quickly and conveniently.

3.Delivering film mechanism and the tensity voluntarily adjusts.

4.PLC programmable procedure control system.

5.Double air blowers,guarantees the temperature balance in the shrink stove with PAD temperature controller, that apparently saves energy.

6.It applies wing shape stainless steel heating system, which is durable for long time use.

7.The heatproof Bolivian filament special fluorine dragon transportation net belt is used in shrink part to ensure the steady of transportation and high strengthen wear proof.

8.Adopt invert speed control net belt conveying mechanism.

9.The height of the conveyer shall be made towards client’s demand, and usually adjusting scope is 800±30mm

10.The direction of bottle entering can be adjusted according to client’s demand.

Technical Parameter

| Max. Package dimension | L420×W278×H390mm |

| Min. Package dimension | L210×W140×H100mm |

| Material of shrink film | PE |

| Thickness of shrink film | 0.03-0.15mm(can custom made) |

| Thermal shrink temperature | It can be adjusted freely under 260℃ |

| Max capacity per hour | 720bags |

| Total heating power | 18kw |

| Actual power | 15kw/h |

| Working air pressure | 0.6-0.8MPA |

| air consumption capacity | 0.3m³/min |

| Gross weight | 1500kg |

Working video

About us

We have more than 20 years knowledge and experience on PET Water/juice/carbonated drinks production line. Our exporting product includes: Injection molding machine, PET preform mould, plastic bottle blowing machine, Water treatment system, Filling machine and Packaging machine etc.

Q: What is the warranty if we buy your machines?

A: We offer the high quality machines with 1 year guarantee start from the machine reach to your factory. Also your share the lifelong technical support.

Q: How about the spare parts?

A: We will send one year enough spare parts together with machines for your stock. During the warranty time, if some spare parts broke without human problem, we will send free for you.

Q: How to install my machines when it arrives? What is the cost?

A: We will send our engineer to your factory to install the machines and train your engineers how to operate and maintain the machines. Customer pay for visa, round-trip tickets, room and accommodation, also USD80/day/ person(engineer salary).

Q: How long time for installation?

A: According to the machine you order, usually we will send one or two engineer, it takes about 7to 20days.

Q: When can I get my machine after I paid?

A: Usually the production time is around 25-60 days. The exactly will be decided by which machine u order.

Reviews

There are no reviews yet.